Spiral mixer

Additional information

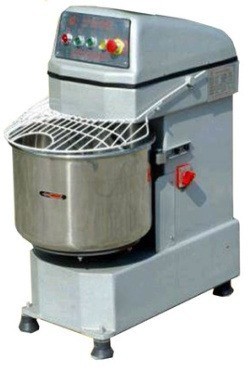

Spiral Mixer 50 Kg

In every professional bakery and food production setup, the demand for efficiency, consistency, and durability never stops. One piece of equipment that has become the backbone of modern baking operations is the Spiral Mixer 50 Kg. Designed for handling large quantities of dough with ease, this machine ensures that every batch is kneaded to perfection, delivering uniform texture, elasticity, and strength.

With its ability to mix up to 50 kilograms of dough at a time, this spiral mixer is the ultimate solution for commercial bakeries, hotels, pizzerias, and food industries. It is more than just a mixer; it is a performance-driven investment that transforms raw ingredients into high-quality dough ready for baking.

What is a Spiral Mixer?

A spiral mixer is a specialized dough mixing machine that uses a spiral-shaped hook to knead large batches of dough. Unlike planetary mixers, which rotate the bowl, the spiral mixer rotates both the hook and the bowl simultaneously. This dual-action ensures that dough is mixed evenly, quickly, and without overheating.

For businesses where dough quality defines the final product, a spiral mixer is essential. The 50 kg capacity version is particularly popular among bakeries and pizzerias that need to handle significant volumes daily.

Why Choose a Spiral Mixer 50 Kg?

High Capacity

This mixer can handle up to 50 kilograms of dough in one cycle, making it ideal for commercial-scale operations.

Superior Dough Quality

The spiral action develops gluten efficiently, producing smooth, elastic dough with perfect hydration.

Time Efficiency

Mixing large batches manually or with smaller mixers can take hours. This machine reduces mixing time drastically while ensuring consistency.

Energy Efficient

Despite its large capacity, the mixer is engineered to consume minimal energy, making it both cost-effective and eco-friendly.

Durability

Made from high-grade stainless steel, the machine is built to withstand continuous use in demanding environments.

Key Features of the Spiral Mixer 50 Kg

Dual Rotation System

Both the bowl and spiral hook rotate simultaneously, ensuring thorough and uniform mixing.

Sturdy Stainless Steel Bowl

The mixing bowl is made from food-grade stainless steel, resistant to rust, corrosion, and damage.

Powerful Motor

Equipped with a heavy-duty motor, the mixer runs smoothly even under full load, ensuring reliability in high-volume production.

Two-Speed Operation

Most models come with low and high speeds, allowing bakers to control dough development based on recipes.

Safety Features

Emergency stop buttons, bowl guards, and automatic shut-off systems ensure operator safety.

Easy Maintenance

The design allows quick cleaning and maintenance, essential for hygiene and long-term use.

Applications of Spiral Mixer 50 Kg

Commercial Bakeries

Ideal for producing bread dough, rolls, buns, and artisan loaves in bulk.

Pizzerias

Perfect for creating large quantities of pizza dough with consistent elasticity and strength.

Hotels and Restaurants

For establishments that prepare fresh bread, pastries, and specialty items daily, this mixer is a necessity.

Food Production Units

Industrial kitchens and packaged food manufacturers use it to maintain uniform quality across batches.

Benefits Over Smaller Mixers

Large Batch Handling

Instead of mixing small batches repeatedly, the 50 kg mixer handles everything in one go, saving time.

Consistency

Every batch of dough has the same hydration, texture, and elasticity, ensuring uniform results.

Reduced Labor Costs

Less manual intervention is needed, cutting down labor costs and physical effort.

Professional Finish

Products prepared from dough mixed in this machine rise better, bake evenly, and maintain consistent taste.

How It Works

-

Loading Ingredients – Flour, water, yeast, and other ingredients are added to the bowl.

-

Spiral Action Begins – The spiral hook and bowl rotate simultaneously.

-

Low-Speed Mixing – Ingredients are combined into a uniform mass.

-

High-Speed Kneading – The dough develops gluten, becoming elastic and ready for fermentation.

-

Completion – Within minutes, the mixer produces a perfectly kneaded batch ready for proofing and baking.

Factors to Consider Before Buying

Capacity

Ensure the 50 kg capacity aligns with your production requirements.

Motor Power

Choose a machine with a strong motor for uninterrupted performance.

Build Quality

Opt for stainless steel construction for hygiene and durability.

Safety Standards

Check for guards, emergency stops, and certifications.

Brand Reputation

Select a trusted manufacturer known for quality service and support.

Maintenance Tips

-

Clean After Each Use – Wipe down the bowl and spiral hook to prevent dough buildup.

-

Check Electrical Components – Regularly inspect wiring and switches.

-

Lubricate Moving Parts – Keeps the machine running smoothly.

-

Inspect Safety Guards – Ensure all protective features function correctly.

-

Annual Servicing – Professional maintenance extends the lifespan of the mixer.

Why It’s Essential for Modern Baking

In today’s competitive bakery market, efficiency is not optional—it’s a necessity. Customers demand consistency, freshness, and high-quality products daily. The Spiral Mixer 50 Kg ensures that bakeries can meet this demand without strain, combining high-capacity performance with outstanding dough quality.

With this machine, bakeries not only improve productivity but also enhance product quality, reduce operational costs, and strengthen their brand reputation. It is a reliable partner that supports long-term growth and customer satisfaction.

Final Thoughts

For bakeries, pizzerias, hotels, and food production units, investing in the right equipment defines success. The Spiral Mixer 50 Kg is more than just a mixing machine; it is a cornerstone of efficiency, consistency, and quality. Its large capacity, robust design, and advanced features make it a must-have for businesses that aim to grow while maintaining excellence.

By streamlining dough preparation, this machine allows bakers to focus on creativity, customer service, and expanding their business. It ensures that every loaf, bun, or pizza dough meets the highest professional standards. In the fast-paced world of food production, the spiral mixer is not just an option—it’s a necessity for anyone serious about success.