Description

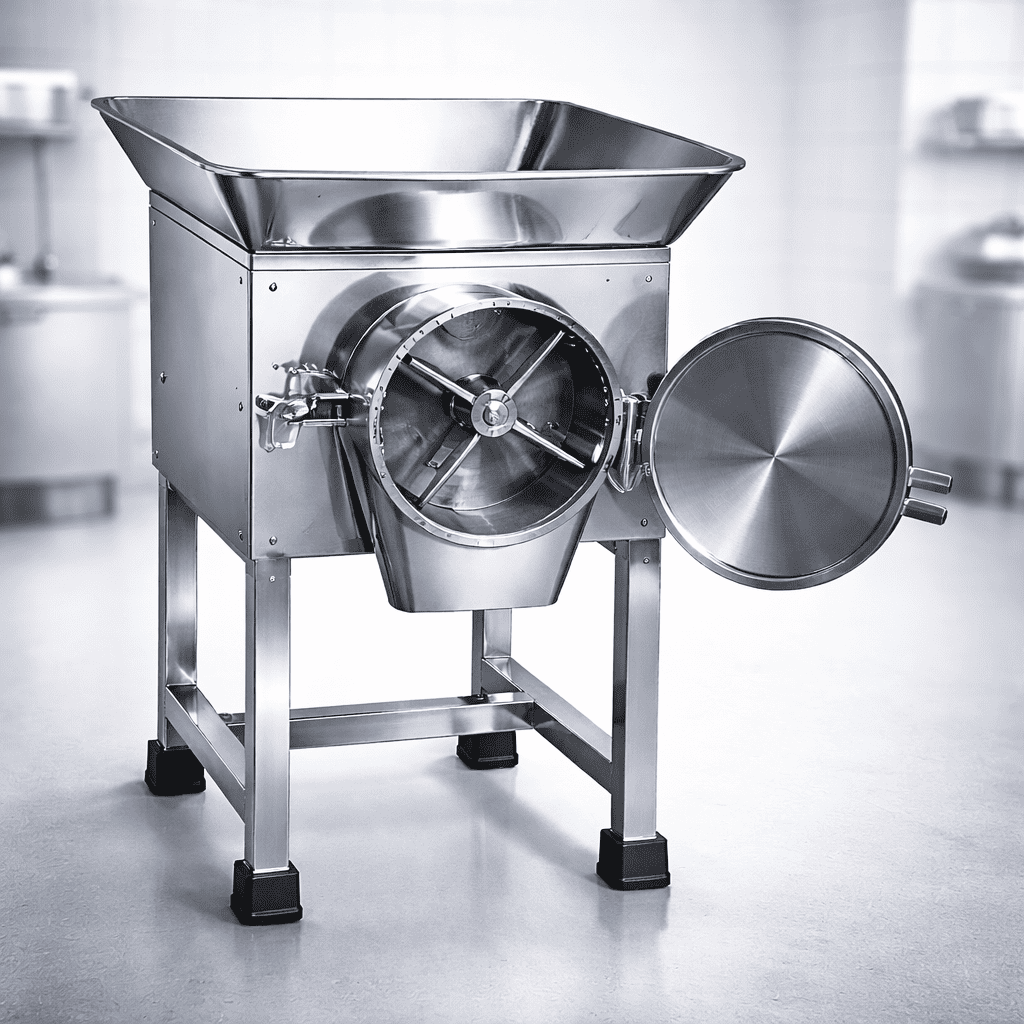

Pulverizer (Electric)

Introduction to Efficient Food Processing

In modern kitchens, food processing has moved beyond simple chopping and grinding. Businesses and large households alike require equipment that combines speed, efficiency, and precision. The Pulverizer (Electric) is a game-changing appliance that streamlines food preparation, turning raw ingredients into fine powders, pastes, or semi-solid forms effortlessly. Whether for spices, grains, or herbs, this machine guarantees uniform results, helping chefs, caterers, and food manufacturers maintain high standards of quality and productivity.

What is a Pulverizer (Electric)?

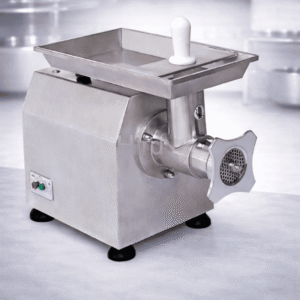

A pulverizer is an electric-powered machine designed to crush, grind, and pulverize a variety of food items into fine powders or pastes. Unlike manual grinders, an electric pulverizer uses high-speed motors and robust blades to process ingredients efficiently. Its design ensures minimal effort, maximum output, and consistent texture, making it ideal for commercial kitchens, restaurants, and food processing units.

Why Modern Kitchens Need a Pulverizer (Electric)

In today’s fast-paced culinary world, efficiency is paramount. Manual grinding is labor-intensive, time-consuming, and often inconsistent. The Pulverizer (Electric) addresses these challenges by:

-

Reducing preparation time drastically.

-

Ensuring uniform grinding for better taste and texture.

-

Minimizing human effort and fatigue.

-

Enhancing hygiene with enclosed, electric operation.

This combination of speed, consistency, and convenience makes it an essential appliance for professional kitchens.

Key Features That Make It Powerful(Pulverizer (Electric))

Electric pulverizers are designed with features that improve functionality, safety, and longevity:

-

High-speed motor – Provides rapid and efficient grinding.

-

Stainless steel body – Ensures durability and hygienic processing.

-

Sharp and robust blades – Handle hard spices, grains, and herbs effortlessly.

-

Safety locking system – Prevents accidents during operation.

-

Easy-to-clean design – Detachable parts for hassle-free maintenance.

These features make it a reliable and long-lasting solution for both commercial and home use.

Applications of a Pulverizer (Electric)

The versatility of this machine is one of its strongest selling points:

-

Grinding spices into fine powders for culinary use.

-

Pulverizing grains, rice, and lentils for flour or batter.

-

Creating pastes from herbs, chilies, and garlic.

-

Preparing powders for pharmaceutical or cosmetic applications.

-

Crushing dried fruits or nuts for bakery ingredients.

This adaptability makes it an indispensable tool in diverse industries.

Benefits of Using a Pulverizer (Electric)

Investing in a quality pulverizer offers numerous advantages:

-

Consistency – Uniform texture and particle size in every batch.

-

Efficiency – Process large quantities in minimal time.

-

Hygiene – Enclosed processing reduces contamination risks.

-

Durability – Built to withstand heavy-duty use.

-

Cost-effectiveness – Saves labor and reduces ingredient wastage.

These benefits make it a profitable investment for food service and production businesses.

How a Pulverizer (Electric) Works

The operation is simple yet highly effective. Ingredients are fed into the machine through the hopper. Once the motor is powered on, high-speed blades crush and grind the materials, transforming them into fine powders or pastes. Adjustable settings in some models allow control over the fineness of the output, providing flexibility for different culinary or industrial needs.

Types of Pulverizers (Electric)

-

Single-Phase Pulverizers – Designed for small to medium kitchens.

-

Three-Phase Industrial Pulverizers – Handle large-scale production efficiently.

-

Multi-Functional Pulverizers – Grind spices, grains, herbs, and even dry fruits.

-

Compact Home Models – Suitable for domestic kitchens with limited space.

Each type caters to different requirements, from commercial to household use.

Safety Features and Guidelines(Pulverizer (Electric))

Safety is paramount in electric kitchen equipment. Modern pulverizers incorporate:

-

Overload protection – Prevents motor damage.

-

Safety interlock – Ensures the machine runs only when securely closed.

-

Anti-slip base – Prevents accidents during operation.

-

Thermal cut-off – Protects the motor from overheating.

Adhering to safety guidelines ensures reliable and risk-free usage.

Maintenance and Care(Pulverizer (Electric))

Proper care enhances longevity and performance:

-

Clean the hopper and blades after each use.

-

Avoid grinding overly hard substances that may damage blades.

-

Periodically check the motor and electrical connections.

-

Store in a dry, dust-free environment.

Regular maintenance ensures the machine remains efficient and durable.

Role in Food Industry and Restaurants(Pulverizer (Electric))

Commercial kitchens, restaurants, and food processing units rely on pulverizers for:

-

Efficient spice powder production.

-

Preparation of pastes for curries, sauces, and marinades.

-

Consistency in baked goods and confectionery.

-

Reducing manual labor while maintaining high output.

Its efficiency improves workflow, enhances productivity, and ensures consistent quality.

Enhancing Culinary Creativity(Pulverizer (Electric))

With a pulverizer, chefs and food manufacturers can experiment with:

-

Blending custom spice mixes.

-

Creating new sauces and pastes.

-

Producing unique flours or powders for specialty recipes.

-

Developing innovative recipes with consistent textures.

The appliance encourages creativity while maintaining precision.

Energy Efficiency and Eco-Friendly Design(Pulverizer (Electric))

Modern electric pulverizers are designed to consume minimal electricity while providing maximum output. High-efficiency motors reduce power usage, and energy-saving features ensure the machine operates optimally, aligning with sustainable kitchen practices.

Durability and Long-Term Investment

Built with high-quality materials and robust engineering, electric pulverizers offer long-term reliability. Stainless steel bodies resist corrosion, while high-grade blades retain sharpness over time. Investing in a quality machine ensures years of uninterrupted performance, making it cost-effective for commercial and household use.

Versatility Beyond Food

While primarily used for culinary applications, electric pulverizers are valuable in:

-

Pharmaceutical production for grinding tablets or herbs.

-

Cosmetic industries for creating powders or herbal blends.

-

Chemical labs for processing non-toxic materials.

This versatility expands their usability across industries.

Why Businesses Choose Pulverizers (Electric)

Businesses value these machines for the efficiency, consistency, and hygiene they bring to food preparation. By reducing manual labor, speeding up production, and maintaining uniform results, they help organizations deliver high-quality products and satisfy customer expectations.

Innovations in Modern Pulverizers

Technological advancements have made modern pulverizers more user-friendly and efficient. Digital controls, adjustable speed settings, and automated grinding cycles enhance precision. Some models even feature multiple blades for faster processing and uniform grinding, ensuring top-notch results every time.

Final Thoughts

The Pulverizer (Electric) is more than a kitchen appliance; it is a cornerstone of efficiency, precision, and culinary excellence. Its ability to transform raw ingredients into fine powders, pastes, or blended forms with consistency makes it indispensable in professional kitchens, food processing units, and even household settings. Investing in a high-quality electric pulverizer ensures superior performance, enhanced productivity, and reliable long-term service.

Reviews

There are no reviews yet.