Description

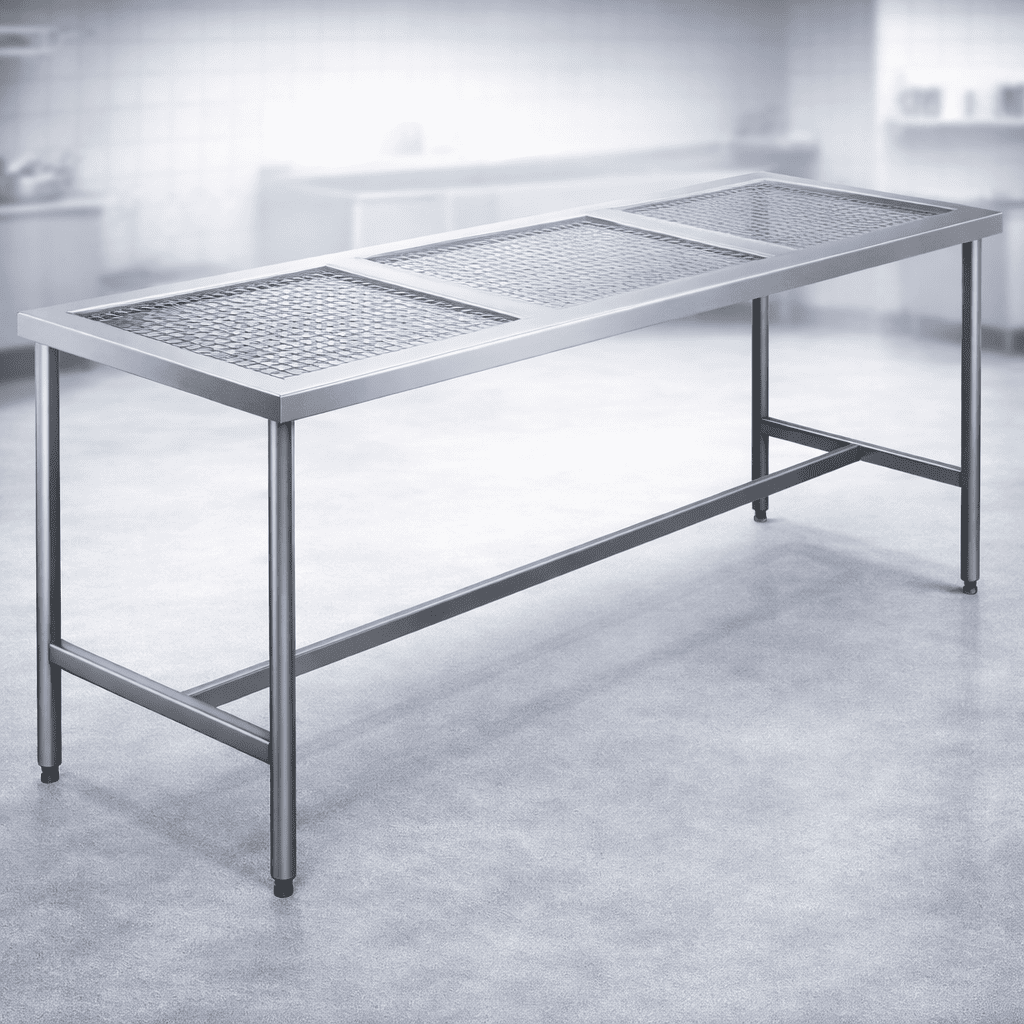

Perforated Cleaning Table

Introduction to Efficient Kitchen and Industrial Cleaning

Maintaining cleanliness and hygiene in kitchens, food processing units, and industrial environments is vital for operational efficiency and safety. A Perforated Cleaning Table is a specialized workstation designed to simplify washing, draining, and cleaning tasks. Its innovative design ensures optimal water drainage, improves workflow, and reduces manual labor, making it an essential appliance for commercial kitchens, hotels, hospitals, and food processing industries.

What is a Perforated Cleaning Table?

A perforated cleaning table is a robust workstation featuring a perforated or slotted surface that allows water, liquids, and small debris to pass through during cleaning operations. Constructed from high-grade stainless steel, it resists corrosion, rust, and daily wear while providing a hygienic and durable workspace. These tables are designed for washing vegetables, fruits, meat, seafood, utensils, and other kitchen or industrial items efficiently.

Importance of Perforated Cleaning Tables in Modern Operations

Manual cleaning and draining can be inefficient, messy, and time-consuming. A Perforated Cleaning Table provides:

-

Efficient water drainage to prevent waterlogging.

-

Hygienic surfaces that reduce contamination risks.

-

Durable and corrosion-resistant materials for long-term use.

-

Ergonomic design that enhances staff comfort and productivity.

This combination of efficiency, hygiene, and durability makes perforated cleaning tables indispensable in professional settings.

Key Features That Make Perforated Cleaning Tables Exceptional

Modern perforated cleaning tables are equipped with features to enhance cleaning efficiency:

-

Perforated surface – Allows water and small debris to drain quickly.

-

Stainless steel construction – Durable, hygienic, and easy to clean.

-

Reinforced structure – Supports heavy loads and continuous use.

-

Ergonomic height and design – Reduces strain on operators.

-

Splash guards and side panels – Keep surrounding areas clean.

-

Optional under-shelves or storage – Adds functionality for organized workflows.

These features ensure reliable performance, hygiene, and safety in high-volume environments.

Applications of Perforated Cleaning Tables

Perforated cleaning tables are versatile and used in multiple environments:

-

Washing and draining vegetables and fruits in commercial kitchens.

-

Cleaning meat, seafood, and poultry in food processing units.

-

Pre-rinsing utensils and trays in hotels and catering services.

-

Maintaining hygienic workflows in hospitals and industrial kitchens.

-

Supporting high-volume operations with durability and efficiency.

Their multifunctionality makes them an essential component of professional cleaning setups.

Benefits of Using a Perforated Cleaning Table

Investing in a perforated cleaning table provides numerous advantages:

-

Efficiency – Quick drainage and easy cleaning reduce operation time.

-

Hygiene – Promotes contamination-free cleaning with stainless steel surfaces.

-

Durability – Heavy-duty construction withstands continuous usage.

-

Ergonomics – Minimizes operator fatigue and improves workflow.

-

Versatility – Suitable for multiple cleaning tasks across various industries.

These benefits make it a critical appliance for kitchens, food processing units, and industrial settings.

How a Perforated Cleaning Table Works

The operation is straightforward yet highly effective. Items are placed on the perforated surface, allowing water, small debris, and leftover particles to pass through the holes. High-pressure sprays, washing brushes, or hand cleaning can be performed efficiently without water pooling on the table surface. Wastewater flows into underlying drainage systems, keeping the workspace clean and organized.

Types of Perforated Cleaning Tables

-

Single-Level Tables – Ideal for small kitchens or low-volume operations.

-

Double-Level or Multi-Tier Tables – Provide additional workspace and storage.

-

Integrated Sink Tables – Combine perforated surfaces with sinks for more efficient cleaning.

-

Heavy-Duty Industrial Tables – Suitable for meat, seafood, and high-volume processing.

-

Customizable Tables – Adaptable to kitchen layouts and workflow requirements.

Choosing the right type depends on operational volume, space, and specific cleaning tasks.

Enhancing Workflow Productivity

A Perforated Cleaning Table streamlines cleaning and preparation workflows. Staff can wash, rinse, and drain items efficiently in one ergonomic workstation. This reduces preparation time, prevents clutter, and ensures a hygienic and organized work environment—critical for high-volume kitchens and food processing units.

Safety Features and Guidelines

Safety is crucial in busy cleaning environments:

-

Splash guards and side panels – Prevent water from spilling onto the floor.

-

Non-slip flooring or footpads – Reduce risk of accidents around wet workstations.

-

Ergonomic height and design – Minimizes physical strain and repetitive motion injuries.

-

Sturdy construction – Supports heavy loads safely without tipping or collapse.

Following proper safety protocols ensures efficient and secure operation.

Maintenance and Care

Proper maintenance ensures long-term durability and hygiene:

-

Regularly clean the perforated surface and underlying drainage system.

-

Use non-abrasive cleaning agents to maintain stainless steel integrity.

-

Inspect table legs, joints, and welds for structural stability.

-

Sanitize surfaces to meet food safety and hygiene standards.

Routine maintenance guarantees optimal performance and longevity.

Role in Commercial Kitchens and Food Processing

Perforated cleaning tables are indispensable in professional environments:

-

Efficiently prepare vegetables, fruits, and meat for cooking or processing.

-

Maintain a sanitary workflow in restaurants, hotels, and catering services.

-

Enhance hygiene in hospitals, cafeterias, and industrial kitchens.

-

Support organized and fast-paced kitchen operations with high efficiency.

This appliance is essential for operations that demand cleanliness, durability, and productivity.

Energy Efficiency and Eco-Friendly Design

Modern perforated cleaning tables promote sustainability and efficiency:

-

Stainless steel is fully recyclable and corrosion-resistant.

-

Efficient drainage minimizes water usage and waste accumulation.

-

Long-lasting construction reduces the need for frequent replacements.

These features make it environmentally friendly while cost-effective for professional kitchens.

Durability and Long-Term Investment

High-quality perforated cleaning tables are designed to withstand continuous heavy-duty use. Stainless steel surfaces, reinforced structures, and durable legs ensure long-term reliability. Investing in a premium table guarantees years of efficient, hygienic, and safe cleaning operations, reducing downtime and operational costs.

Versatility Beyond Standard Cleaning

While primarily used for washing and draining, perforated cleaning tables also:

-

Serve as prep stations for cutting, sorting, and organizing food items.

-

Facilitate washing and pre-cleaning of trays, utensils, and cookware.

-

Support multiple kitchen or processing tasks in high-volume environments.

-

Integrate seamlessly with sinks, drainage systems, or automated cleaning stations.

This versatility increases their value in both commercial and industrial operations.

Innovations in Modern Perforated Cleaning Tables

Recent technological advancements have enhanced performance and usability:

-

Modular designs allow expansion and customization.

-

Reinforced perforations provide optimal drainage without compromising structural strength.

-

Integrated sinks and drainboards improve workflow efficiency.

-

Ergonomic enhancements reduce strain and improve operator comfort.

These innovations make modern perforated cleaning tables more efficient, durable, and user-friendly.

Why Every High-Volume Kitchen Needs a Perforated Cleaning Table

A Perforated Cleaning Table is essential for kitchens, catering services, hospitals, and food processing units that handle large volumes of cleaning tasks daily. It saves time, improves hygiene, reduces labor, and ensures consistent results. By automating drainage and providing an ergonomic workstation, it enhances overall operational efficiency.

Final Thoughts

The Perforated Cleaning Table is more than a workstation—it is a powerful solution for modern kitchens and industrial operations. With durable stainless steel construction, ergonomic design, and perforated surfaces for efficient drainage, it ensures fast, hygienic, and organized cleaning of kitchenware, produce, and utensils. Investing in a premium perforated cleaning table guarantees superior productivity, consistent hygiene, and long-term reliability, making it an indispensable appliance for commercial kitchens, hotels, catering services, and food processing units.

Reviews

There are no reviews yet.