Description

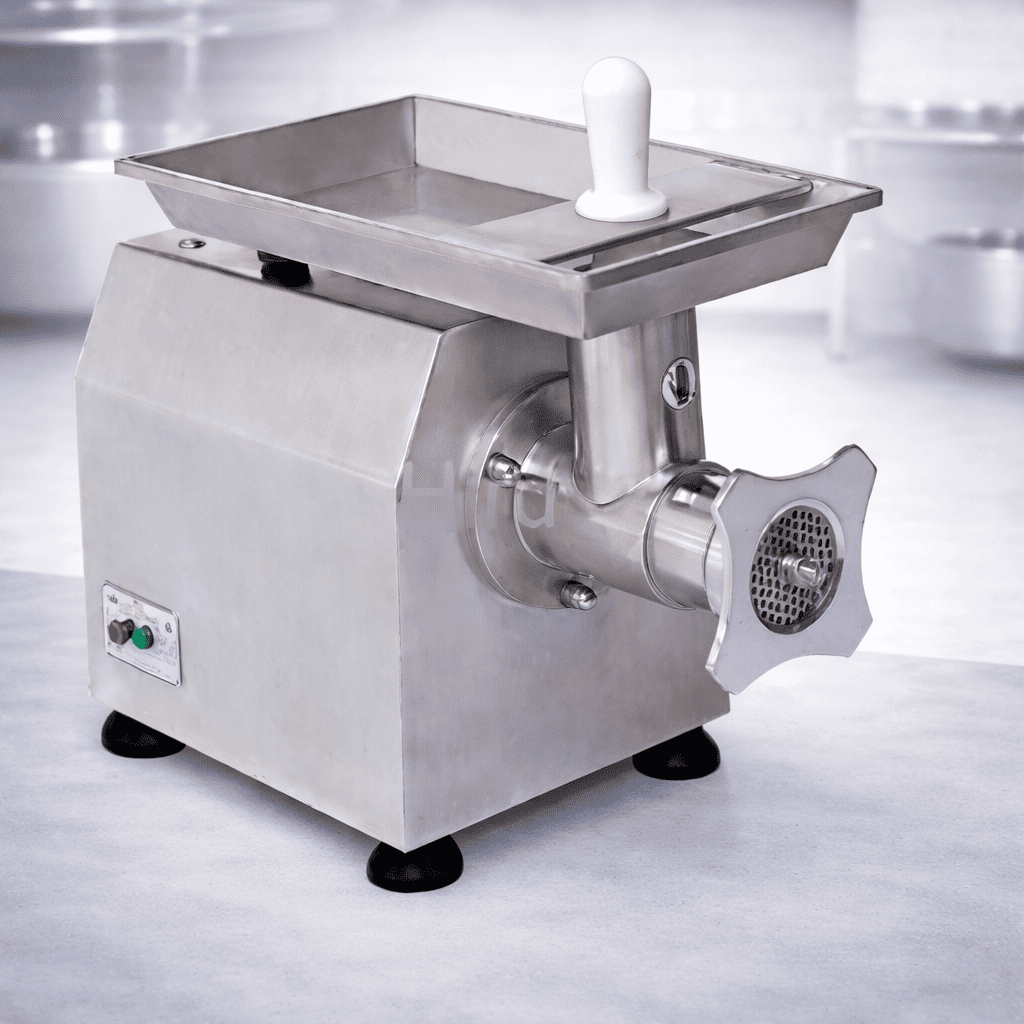

Meat Mincer

Introduction to Efficient Meat Processing

In professional kitchens, butcheries, and food processing units, speed, precision, and hygiene are crucial. A Meat Mincer is an essential appliance that transforms large chunks of meat into finely minced portions, ready for various culinary applications. Ideal for restaurants, hotels, catering services, and households, it ensures consistent quality, reduces labor, and streamlines workflow.

What is a Meat Mincer?

A meat mincer is a specialized appliance designed to finely chop or grind meat into uniform textures suitable for sausages, patties, burgers, and other dishes. Constructed from durable materials like stainless steel, it withstands continuous operation while maintaining hygiene and safety standards. Modern meat mincers are available in manual, electric, and commercial-grade variants to suit different kitchen requirements.

Importance of Mincers in Modern Kitchens

Manual chopping of meat is labor-intensive, time-consuming, and often inconsistent. A Meat Mincer offers:

-

Faster processing of large quantities of meat.

-

Consistent texture for culinary and commercial applications.

-

Hygienic operation, minimizing direct contact with raw meat.

-

Safety features that reduce the risk of injuries.

This combination of speed, precision, and hygiene makes meat mincers indispensable in both professional and domestic kitchens.

Key Features That Make Mincers Exceptional

Modern meat mincers are designed with several advanced features:

-

High-capacity grinding drum – Handles large volumes of meat efficiently.

-

Powerful motor – Ensures uniform and smooth grinding.

-

Stainless steel construction – Durable, rust-resistant, and easy to clean.

-

Interchangeable cutting plates – Provides coarse, medium, or fine grinding options.

-

Safety mechanisms – Prevent accidental injuries during operation.

-

Ergonomic design – Promotes ease of use for extended kitchen operations.

These features guarantee efficiency, reliability, and long-lasting performance in demanding kitchen environments.

Applications of Mincers

A meat mincer is versatile and serves multiple culinary purposes:

-

Preparing ground meat for burgers, kebabs, and meatballs.

-

Processing meat for sausages, pâtés, and other delicacies.

-

Grinding poultry, beef, lamb, or fish for recipes.

-

Prepping meat for catering services, banquet events, or restaurants.

-

Ensuring consistent portion sizes for commercial food production.

Its multifunctionality makes it essential for both professional chefs and home cooks.

Benefits of Using a Mincer

Investing in a high-quality meat mincer offers numerous advantages:

-

Consistency – Ensures uniform minced texture for better cooking results.

-

Time-saving – Speeds up meat preparation processes.

-

Hygiene – Stainless steel surfaces and enclosed design prevent contamination.

-

Durability – Constructed to withstand high-volume use.

-

Safety – Reduces risk of cuts compared to manual chopping.

These benefits make it a vital appliance for modern kitchens seeking efficiency and quality.

How a Meat Mincer Works

The operation is simple yet highly effective. Meat is fed into the mincer’s hopper, where a rotating screw pushes it through cutting blades and plates. The result is finely minced meat with uniform texture. Modern electric meat mincers may feature variable speed controls, reverse functions for unclogging, and removable parts for easy cleaning, ensuring safe and efficient operation.

Types of Mincers

-

Manual Meat Mincers – Suitable for small-scale or domestic use.

-

Electric Meat Mincers – High-capacity units for restaurants and commercial kitchens.

-

Industrial Meat Mincers – Designed for butchers, meat processing units, and large-scale operations.

-

Compact Domestic Mincers – Lightweight units for household kitchens.

-

Multi-functional Mincers – Can process meat, vegetables, and other ingredients.

Choosing the right type depends on usage volume, kitchen size, and operational requirements.

Enhancing Kitchen Efficiency

A Meat Mincer significantly improves kitchen productivity. By automating the grinding process, staff can handle large quantities of meat quickly, reduce prep time, and maintain consistent quality across all dishes. This efficiency is particularly valuable in commercial kitchens and catering services.

Safety Features and Guidelines

Safety is critical when handling meat processing equipment:

-

Protective covers and interlocks – Prevent accidental contact with blades.

-

Non-slip feet or casters – Ensure stability during operation.

-

Overload protection – Safeguards the motor from damage.

-

Ergonomic handles and feed mechanisms – Reduce operator strain and risk of injury.

Following safety guidelines ensures secure and reliable operation.

Maintenance and Care

Proper maintenance ensures long-term performance and hygiene:

-

Clean all parts, including blades, plates, and the hopper, after each use.

-

Avoid abrasive materials that may damage stainless steel surfaces.

-

Regularly check for wear and tear on cutting plates and screws.

-

Lubricate moving parts if recommended by the manufacturer.

Routine care guarantees durability, hygiene, and operational efficiency.

Role in Restaurants, Hotels, and Catering Services

Commercial kitchens depend on meat mincers to:

-

Process large quantities of meat efficiently.

-

Maintain hygiene and consistent texture.

-

Reduce labor and operational costs.

-

Ensure high-quality output for burgers, kebabs, sausages, and other dishes.

This appliance is essential for maintaining culinary standards in professional kitchens.

Energy Efficiency and Eco-Friendly Design

Modern meat mincers are designed to optimize power consumption while maintaining high performance:

-

Energy-efficient motors reduce electricity usage.

-

Durable construction minimizes replacement frequency.

-

Stainless steel materials are recyclable and environmentally friendly.

These features make meat mincers both cost-effective and eco-conscious.

Durability and Long-Term Investment

High-quality meat mincers are built to withstand continuous use. Stainless steel construction, reinforced blades, and powerful motors ensure long-term reliability. Investing in a premium meat mincer is a cost-effective solution that guarantees consistent performance over years of operation.

Versatility Beyond Meat

While primarily used for meat, modern meat mincers can also:

-

Process vegetables and fruits for sauces, purees, and fillings.

-

Grind fish and seafood for patties and fish balls.

-

Prepare ingredients for mixed dishes and catering events.

-

Support pre-processing for soups, stews, and gravies.

This versatility increases the appliance’s value in both domestic and commercial kitchens.

Innovations in Modern Mincers

Technological advancements have enhanced meat mincers:

-

Variable speed controls for precise grinding.

-

Reverse function for clearing blockages.

-

Removable and dishwasher-safe components for easy cleaning.

-

Safety interlocks and ergonomic designs for operator comfort.

These innovations improve efficiency, safety, and user experience.

Why Every Kitchen Needs a Mincer

A Meat Mincer is indispensable in kitchens handling large volumes of meat. It saves time, improves consistency, enhances hygiene, and reduces manual labor. For restaurants, catering services, butcheries, and food processing units, it is a critical tool for maintaining quality, efficiency, and safety.

Final Thoughts

The Meat Mincer is more than a kitchen appliance—it is a cornerstone for professional culinary operations. Its durable construction, powerful motor, and versatile design make it essential for preparing high-quality minced meat quickly and safely. By reducing labor, ensuring uniform texture, and maintaining hygiene, it transforms meat preparation into a faster, safer, and more efficient process. Investing in a high-quality meat mincer guarantees superior performance, durability, and consistency, making it a must-have for modern kitchens and commercial food operations.

Reviews

There are no reviews yet.