Description

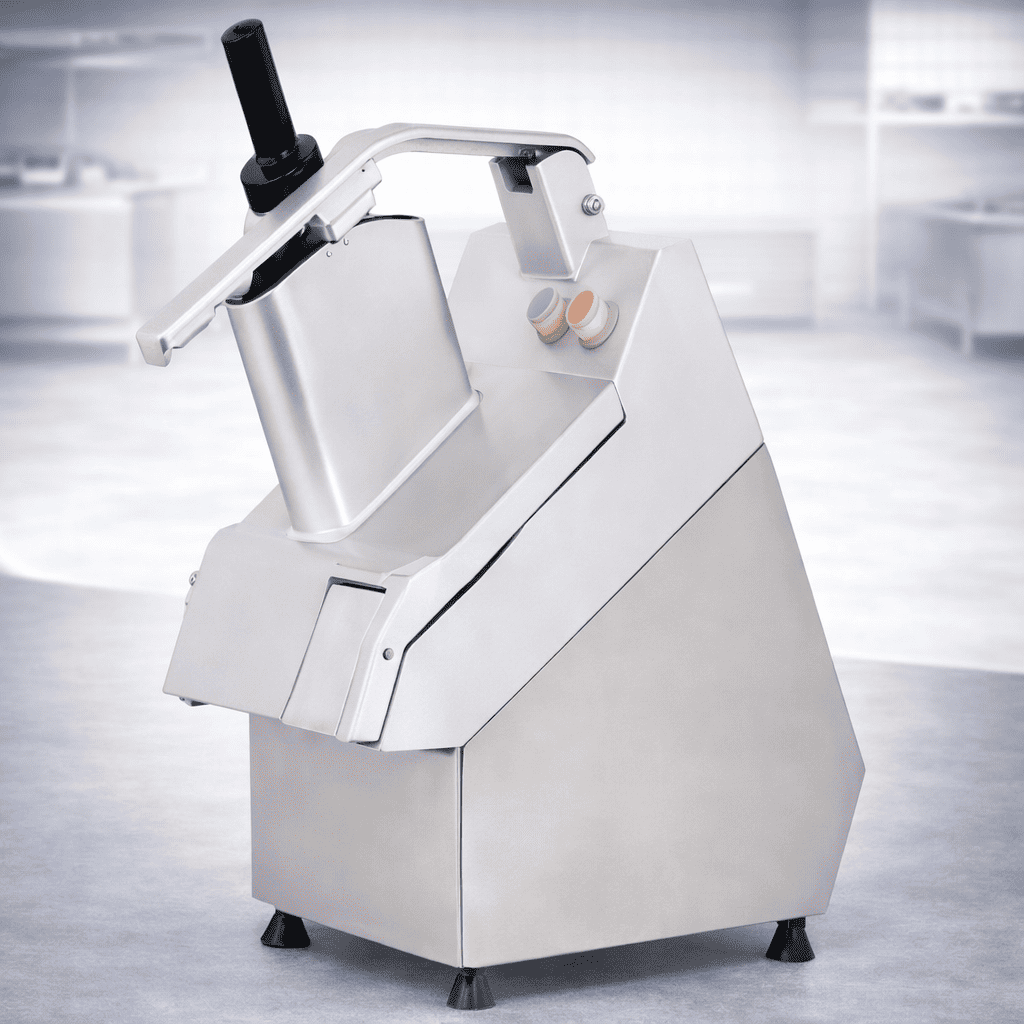

Electric Vegetable Cutter Machine

Introduction to Efficient Vegetable Preparation

In modern kitchens, speed, precision, and hygiene are critical. An Electric Vegetable Cutter Machine is an indispensable appliance that automates the process of chopping, slicing, and dicing vegetables, reducing manual labor while ensuring consistent results. Ideal for commercial kitchens, restaurants, hotels, and catering services, this machine enhances productivity, saves time, and maintains high standards of food preparation.

What is an Electric Vegetable Cutter Machine?

An electric vegetable cutter machine is a powerful kitchen appliance designed to cut vegetables uniformly in various shapes and sizes. Equipped with high-speed blades and multiple attachments, it can slice, dice, chop, and julienne efficiently. Constructed from high-quality stainless steel and durable plastics, it ensures long-lasting performance and hygienic operation in demanding kitchen environments.

Importance of Vegetable Cutter Machines in Modern Kitchens

Manual chopping is labor-intensive, time-consuming, and often inconsistent. An Electric Vegetable Cutter Machine provides:

-

Faster preparation of large quantities of vegetables.

-

Consistent and uniform cuts for better presentation and cooking.

-

Hygienic operation, minimizing direct contact with food.

-

Enhanced efficiency and reduced labor in commercial kitchens.

This combination of speed, consistency, and hygiene makes it essential for modern culinary operations.

Key Features That Make Electric Vegetable Cutter Machines Exceptional

Modern electric vegetable cutter machines come with advanced features to maximize efficiency:

-

High-speed motor – Ensures rapid and precise cutting.

-

Multiple attachments and blades – Allows slicing, dicing, chopping, and julienne cuts.

-

Stainless steel construction – Durable, rust-resistant, and hygienic.

-

Safety mechanisms – Prevents accidental contact with blades.

-

Large capacity feed chute – Accommodates a variety of vegetable sizes.

-

Ergonomic design – Ensures comfort and ease of use for extended operations.

These features guarantee reliability, efficiency, and safe operation in commercial kitchens.

Applications of Electric Vegetable Cutter Machines

A vegetable cutter machine is highly versatile and supports multiple culinary tasks:

-

Preparing vegetables for salads, soups, and curries.

-

Cutting potatoes, carrots, cabbage, and other vegetables for large-scale cooking.

-

Slicing onions, tomatoes, and cucumbers uniformly for presentation.

-

Prepping ingredients for catering services, hotels, and restaurants.

-

Reducing manual labor while improving workflow efficiency.

Its multifunctionality makes it indispensable in both professional and large-scale domestic kitchens.

Benefits of Using an Electric Vegetable Cutter Machine

Investing in a high-quality electric vegetable cutter machine offers numerous advantages:

-

Consistency – Produces uniform cuts, enhancing food presentation.

-

Time-saving – Speeds up vegetable preparation significantly.

-

Hygiene – Minimizes contact with raw food, maintaining sanitary standards.

-

Durability – Designed to withstand frequent use in busy kitchens.

-

Safety – Reduces the risk of accidental cuts during manual chopping.

These benefits make it a vital appliance for kitchens aiming for efficiency and quality.

How an Electric Vegetable Cutter Machine Works

The operation is simple and highly effective. Vegetables are fed into the machine’s feed chute, where rotating blades slice, dice, or chop them uniformly. Modern machines feature adjustable settings for different cuts, detachable trays for easy collection, and safety interlocks to prevent accidental operation. The result is perfectly processed vegetables ready for cooking or serving.

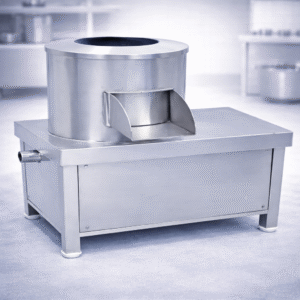

Types of Electric Vegetable Cutter Machines

-

Commercial Vegetable Cutter Machines – High-capacity units suitable for restaurants and catering.

-

Domestic Electric Cutter Machines – Compact and lightweight models for household kitchens.

-

Multi-functional Cutter Machines – Capable of slicing, dicing, and julienne cutting.

-

Stainless Steel Cutter Machines – Durable, hygienic, and ideal for heavy-duty operations.

-

Modular and Attachments-Based Machines – Offer flexibility for various cutting tasks.

Choosing the right type depends on kitchen size, volume of preparation, and intended use.

Enhancing Kitchen Efficiency

An Electric Vegetable Cutter Machine significantly improves workflow by automating labor-intensive tasks. Staff can chop, slice, and dice vegetables in minutes, reducing preparation time and increasing productivity. This efficiency is particularly valuable in commercial kitchens, hotels, and catering services where large volumes of vegetables are processed daily.

Safety Features and Guidelines

Safety is crucial when operating an electric vegetable cutter machine:

-

Protective covers and interlocks – Prevent accidental contact with high-speed blades.

-

Non-slip feet or casters – Ensure stability during operation.

-

Overload protection – Prevents motor burnout.

-

Ergonomic handles and feed mechanisms – Reduce operator strain and improve safety.

Following proper safety protocols ensures secure and reliable operation.

Maintenance and Care

Proper maintenance ensures long-term durability and hygiene:

-

Clean blades, feed chute, and trays after each use.

-

Avoid abrasive cleaners that may damage stainless steel or plastic components.

-

Regularly check for wear on blades and motor components.

-

Lubricate moving parts if recommended by the manufacturer.

Routine care guarantees optimal performance and long-lasting operation.

Role in Restaurants, Hotels, and Catering Services

Commercial kitchens rely on electric vegetable cutter machines to:

-

Process large quantities of vegetables efficiently.

-

Maintain consistent quality and presentation.

-

Reduce labor and operational costs.

-

Support diverse menu items that require uniform vegetable cuts.

This appliance is essential for professional kitchens to maintain high standards of food preparation.

Energy Efficiency and Eco-Friendly Design

Modern electric vegetable cutter machines are designed to optimize energy usage while delivering high performance:

-

Energy-efficient motors minimize electricity consumption.

-

Durable construction reduces the need for frequent replacements.

-

Stainless steel components are recyclable, promoting eco-friendly practices.

These features make it both cost-effective and environmentally conscious.

Durability and Long-Term Investment

High-quality electric vegetable cutter machines are built for continuous heavy-duty use. Stainless steel blades, reinforced motors, and durable housings ensure long-term reliability. Investing in a premium machine guarantees consistent performance and reduces maintenance costs over time.

Versatility Beyond Standard Cutting

While primarily used for vegetables, modern electric cutter machines can also:

-

Slice fruits for desserts, salads, and garnishes.

-

Chop ingredients for sauces, soups, and stews.

-

Julienne vegetables for specialized dishes.

-

Support pre-prepping for large-scale events or catering.

This versatility maximizes the value of the appliance across various kitchen tasks.

Innovations in Modern Electric Vegetable Cutter Machines

Technological advancements have enhanced these machines:

-

Adjustable speed settings for precision cutting.

-

Removable, dishwasher-safe components for easy cleaning.

-

Multi-function attachments for slicing, dicing, and julienne cutting.

-

Safety interlocks and ergonomic designs to reduce operator fatigue.

These innovations improve efficiency, safety, and overall kitchen workflow.

Why Every Kitchen Needs an Electric Vegetable Cutter Machine

An Electric Vegetable Cutter Machine is indispensable for kitchens that handle large volumes of vegetables daily. It saves time, improves consistency, enhances hygiene, and reduces labor costs. By automating chopping, slicing, and dicing, it allows chefs and kitchen staff to focus on cooking, presentation, and efficiency.

Final Thoughts

The Electric Vegetable Cutter Machine is more than an appliance—it is a powerful tool that transforms vegetable preparation into a faster, safer, and more efficient process. With durable construction, high-speed performance, and versatile cutting capabilities, it is perfect for commercial kitchens, restaurants, hotels, and large-scale catering operations. Investing in a premium electric vegetable cutter machine ensures superior productivity, consistent quality, and long-term reliability, making it a must-have in modern kitchens.

Reviews

There are no reviews yet.