Description

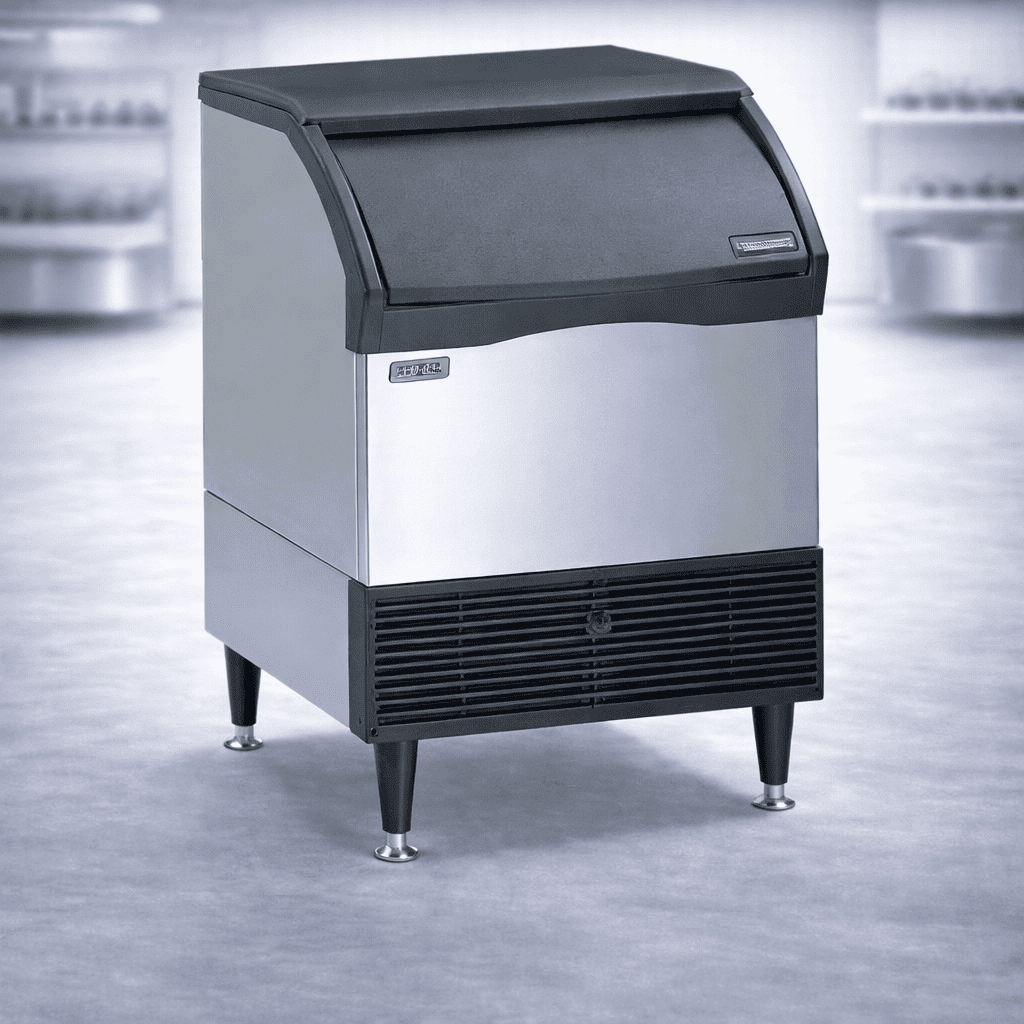

ICE CUBE MAKING MACHINE

In today’s fast-paced hospitality and food service industry, efficiency, quality, and consistency are non-negotiable. Whether it’s a bustling restaurant, a five-star hotel, a catering service, or even a healthcare facility, one essential element remains constant—ice. Guests expect their beverages to be served chilled, cocktails to look flawless, and perishable items to stay fresh. Behind the scenes, this is made possible by the remarkable commercial ice cube machine, a piece of equipment that has transformed modern service standards.

The Essential Role of Ice in Modern Businesses

Ice is more than frozen water—it’s a vital component of customer experience. From refreshing drinks and cocktails to food preservation and medical usage, ice plays a crucial role across industries. In hospitality, perfectly shaped, crystal-clear cubes elevate presentation. In healthcare, clean and hygienic ice is necessary for storage and patient care. This level of demand calls for a reliable machine that guarantees consistency day after day.

What is a Commercial Ice Cube Machine?

A commercial ice cube machine is a specialized appliance designed to produce large volumes of ice efficiently and hygienically. Unlike household freezers that make small batches, these machines are engineered for continuous production, ensuring businesses never run out of ice during peak hours. Depending on design, they can produce different cube sizes, shapes, and clarity to meet diverse requirements.

Key Features of Ice Cube Making Machines

Modern ice cube makers come with cutting-edge features tailored to professional needs:

-

High Production Capacity – Machines are capable of producing anywhere from 20 kg to over 1000 kg of ice per day.

-

Advanced Cooling Systems – Ensures rapid ice formation while conserving energy.

-

Variety of Cube Sizes – Standard, gourmet, crescent, nugget, and flake options.

-

Hygienic Design – Stainless steel exteriors and food-grade interiors prevent contamination.

-

Energy Efficiency – Many models are designed to reduce electricity and water usage.

-

User-Friendly Controls – Digital panels with automated cleaning cycles.

-

Durability – Built for continuous, heavy-duty use in demanding environments.

Benefits of Investing in a Commercial Ice Cube Machine

-

Consistent Ice Supply – No disruption in service during peak demand.

-

Better Beverage Presentation – Crystal-clear cubes improve customer satisfaction.

-

Cost-Effective – Eliminates dependency on purchased ice.

-

Time-Saving – Continuous production reduces manual effort.

-

Space Optimization – Compact yet powerful units maximize kitchen or bar space.

-

Hygiene Control – In-house production ensures safe, clean ice.

Industries That Rely on Ice Cube Machines

The versatility of these machines makes them indispensable across multiple industries:

-

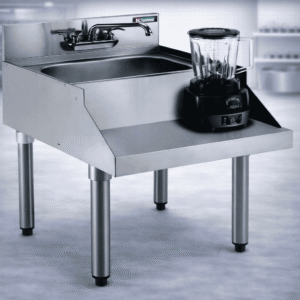

Hotels & Restaurants – For cocktails, juices, soft drinks, and food displays.

-

Bars & Clubs – High demand for premium cocktail ice.

-

Cafés & Juice Shops – Smoothies, iced coffees, and specialty drinks.

-

Hospitals & Clinics – For patient care, storage, and first aid.

-

Catering & Event Services – Ensuring large-scale supply during functions.

-

Retail Stores & Fish Markets – To preserve perishable goods like seafood.

Types of Ice Produced

One of the reasons commercial ice cube machines are so popular is their ability to produce different ice forms:

-

Standard Cubes – Common for restaurants and bars.

-

Gourmet Cubes – Larger, slow-melting cubes perfect for whiskey and cocktails.

-

Crescent Cubes – Space-efficient cubes ideal for dispensers.

-

Flake Ice – Used for food displays and medical applications.

-

Nugget Ice – Soft, chewable ice popular in beverage outlets.

How Does an Ice Cube Machine Work?

The science behind ice cube makers is both simple and innovative:

-

Water enters the machine through a filtration system.

-

The refrigeration unit cools the water against a freezing plate or evaporator.

-

Ice begins to form layer by layer until cubes are complete.

-

The machine releases the cubes into a storage bin.

-

Automatic sensors regulate water levels and ice bin capacity.

This ensures non-stop production with minimal human intervention.

Design and Ergonomics

Manufacturers understand the importance of practicality in commercial kitchens and bars. Most machines are built with:

-

Compact Footprints – Fit into tight spaces without compromising output.

-

Stainless Steel Finish – Provides durability and aesthetic appeal.

-

Noise Reduction Technology – Quiet operation for front-of-house use.

-

Easy Access Panels – For routine cleaning and servicing.

Hygiene and Food Safety Standards

Hygiene is a top priority when producing consumable ice. Reputable machines follow strict safety standards:

-

NSF and HACCP compliance for food safety.

-

Anti-bacterial interiors to prevent biofilm buildup.

-

Self-cleaning cycles for minimal maintenance.

-

Removable filters for clean water supply.

These features guarantee safe and sanitary ice production.

Maintenance and Longevity

Proper maintenance extends the life of your machine:

-

Regularly clean and sanitize water lines.

-

Inspect condenser coils and ventilation areas.

-

Replace filters periodically to maintain water quality.

-

Check for scale buildup in hard-water areas.

With good maintenance, a commercial machine can last for many years, providing an excellent return on investment.

Energy Efficiency and Sustainability

Today’s models are engineered with eco-friendly practices in mind:

-

Reduced energy consumption.

-

Water-saving technologies.

-

Use of environmentally friendly refrigerants.

-

Longer machine lifespan, reducing equipment turnover.

This makes them cost-efficient while aligning with global sustainability goals.

Customization and Capacity Options(Commercial Ice)

Different businesses have different ice needs. Manufacturers offer customization options such as:

-

Adjustable cube size.

-

Higher bin storage capacity.

-

Modular designs for expansion.

-

Built-in or freestanding models.

This ensures businesses get exactly the capacity and functionality they require.

Portable vs Built-In Models

-

Portable Units – Ideal for small businesses or temporary setups.

-

Built-In Units – Perfect for large-scale establishments with high demand.

Choosing the right model depends on space, production needs, and budget.

Common Challenges and Solutions(Commercial Ice)

Like any equipment, ice cube machines face occasional issues:

-

Low Ice Output – Often due to clogged filters or poor ventilation.

-

Strange Taste/Odor – Caused by unclean water lines.

-

Ice Clumping – Can occur if bins are overfilled.

-

Water Leakage – Usually linked to loose fittings.

Routine care and timely servicing resolve these problems quickly.

Case Studies: Real-World Impact(Commercial Ice)

-

Luxury Hotel Chain – Reduced costs by 40% after installing in-house ice machines instead of purchasing ice.

-

Hospital – Improved patient safety with hygienic, filtered ice production.

-

Seafood Market – Extended shelf life of fish and shellfish using consistent flake ice.

These examples highlight the importance of reliable ice-making solutions across industries.

Technological Innovations(Commercial Ice)

Modern advancements have made ice machines smarter:

-

Digital Displays – Show production levels and maintenance alerts.

-

Remote Monitoring – IoT-enabled models for performance tracking.

-

Automatic Descaling – Reduces downtime in hard-water regions.

-

Touchless Dispensing – Enhances hygiene and user experience.

Return on Investment (ROI)

While the upfront cost may seem significant, the ROI is clear:

-

Eliminates recurring purchase of bagged ice.

-

Reduces labor hours wasted on manual ice preparation.

-

Increases customer satisfaction with premium-quality ice.

-

Enhances brand reputation through consistent service.

Future of Ice Cube Making Technology(Commercial Ice)

The future is geared toward smarter, more sustainable machines:

-

AI-powered predictive maintenance.

-

Ultra-energy-efficient cooling systems.

-

Recyclable materials and eco-friendly refrigerants.

-

Compact yet higher-capacity designs.

These advancements will continue to redefine standards in the food service industry.

Why Every Business Needs a Commercial Ice Cube Machine

Simply put, a professional-grade ice maker isn’t a luxury—it’s a necessity. For any business where food, drinks, or perishables are served, reliable ice production ensures smooth operations, satisfied customers, and improved profits.

Final Thoughts

The commercial ice cube machine is more than just a piece of equipment—it is the silent backbone of countless industries. Its ability to produce hygienic, high-quality ice consistently and efficiently makes it indispensable in modern hospitality, healthcare, retail, and event services. With technological innovations, eco-friendly designs, and user-friendly features, these machines are setting new standards of excellence.

For businesses seeking to enhance service quality, reduce costs, and optimize workflow, investing in a commercial ice cube machine is not only practical but also essential for long-term growth and customer satisfaction.

Reviews

There are no reviews yet.