Centrifugal Blower Unit

Additional information

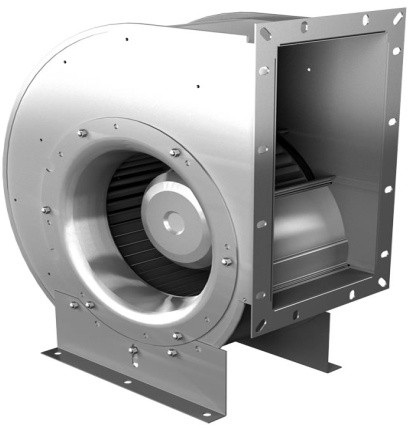

Centrifugal Blower Unit – Powerful Airflow for Industrial and Commercial Applications

Air movement is one of the most critical elements in modern industry, ventilation, and HVAC systems. At the heart of this process lies the Centrifugal Blower Unit, a robust machine engineered to deliver strong, steady, and controlled airflow. Designed for durability and efficiency, centrifugal blowers are widely used in commercial buildings, industrial plants, and specialized environments where reliable air circulation is essential.

A Centrifugal Blower Unit is not just a machine—it’s a powerhouse that ensures productivity, comfort, and safety in countless applications. Whether it’s for cooling machinery, ventilating factories, or enhancing indoor air quality, this unit remains an irreplaceable component in modern infrastructure.

What is a Centrifugal Blower Unit?

A Centrifugal Blower Unit is a mechanical device that uses centrifugal force to move air. Unlike axial fans that push air in a straight direction, centrifugal blowers pull air into the center of the fan and release it at a 90-degree angle through specially designed blades. This process creates higher pressure, making the blower highly efficient for applications that require powerful airflow.

The design of a centrifugal blower allows it to handle high-pressure environments and deliver consistent performance even under challenging conditions. Its versatility makes it suitable for industries such as HVAC, automotive, chemical plants, food processing, and cleanrooms.

Key Components of a Centrifugal Blower Unit

Every Centrifugal Blower Unit is engineered with precision components that work together to create efficient airflow.

Impellers

The impeller is the most vital part of the blower. Its blades rotate at high speed, drawing air in and forcing it outwards through centrifugal force.

Housing

The blower housing encases the impeller and directs the airflow into ducts or designated outlets. It is typically made from durable metals to withstand heavy usage.

Inlet and Outlet

The inlet guides air into the impeller, while the outlet directs the pressurized air to its destination.

Drive Mechanism

Blowers can be belt-driven, direct-driven, or motor-coupled, depending on the application and required efficiency.

Motors

High-efficiency motors power the blower, ensuring reliable performance and minimal energy wastage.

Types of Centrifugal Blower Units

Different designs of centrifugal blowers are available to meet the unique needs of industries.

Forward-Curved Blowers

These have blades curved in the direction of rotation and are commonly used in HVAC systems for medium airflow at low pressure.

Backward-Curved Blowers

Designed for efficiency, backward-curved blades handle higher pressures while consuming less energy.

Radial Blowers

With straight blades, radial blowers are best for applications requiring high pressure and the ability to handle dust-laden air.

Plug Fans

Plug fans are compact centrifugal blowers often integrated into air-handling systems for direct discharge.

Multi-Stage Blowers

Used for extremely high-pressure applications, multi-stage blowers feature multiple impellers in sequence.

Applications of Centrifugal Blower Units

The Centrifugal Blower Unit is highly versatile and used across a wide range of industries.

HVAC Systems

These blowers are integral to heating, ventilation, and air conditioning systems, ensuring consistent air circulation and comfort.

Industrial Ventilation

Factories, warehouses, and workshops use centrifugal blowers to remove dust, fumes, and contaminants, providing workers with a safe environment.

Food and Beverage Processing

Blowers are used for drying, cooling, and ventilation processes to maintain hygiene and efficiency.

Chemical and Pharmaceutical Industries

These units maintain sterile environments and control the distribution of clean air in laboratories and production plants.

Automotive Sector

Centrifugal blowers are used for cooling engines, exhaust systems, and climate control within vehicles.

Cleanrooms and Data Centers

In spaces requiring precise temperature and air quality control, centrifugal blowers ensure consistent airflow and humidity regulation.

Advantages of a Centrifugal Blower Unit

The benefits of using a centrifugal blower are numerous and powerful.

High Efficiency

Centrifugal blowers are engineered to deliver consistent performance even under high-pressure conditions.

Durability

With rugged construction, these blowers withstand long hours of operation in demanding environments.

Versatility

From small-scale HVAC systems to heavy-duty industrial plants, they adapt to multiple applications.

Quiet Operation

Advanced designs reduce noise levels, ensuring smoother operation in sensitive environments.

Energy Savings

Modern centrifugal blowers are designed to consume less power while maximizing airflow output.

Reliability

Built with precision engineering, they provide long service life and minimal breakdowns.

How Does a Centrifugal Blower Unit Work?

The working principle is simple yet powerful. Air enters the blower through the inlet, where it encounters the rapidly rotating impeller. The impeller blades impart kinetic energy to the air, pushing it outward through centrifugal force. This air is then directed into the housing, which converts the velocity into pressure before releasing it through the outlet.

This process ensures a controlled, high-pressure airflow that can be distributed to ducts, workspaces, or equipment, depending on the system’s requirements.

Latest Innovations in Centrifugal Blower Units

Modern technology has revolutionized blower design, making them smarter and more efficient.

Variable Frequency Drives (VFDs)

By controlling motor speed, VFDs optimize energy usage and adapt airflow to real-time requirements.

Noise Reduction Technology

Innovative blade designs and acoustic housing minimize noise during operation.

Smart Monitoring Systems

IoT-enabled blowers provide real-time data on performance, energy use, and predictive maintenance.

Eco-Friendly Materials

Manufacturers are now using recyclable and sustainable materials to reduce environmental impact.

Maintenance and Care of Centrifugal Blower Units

To maintain peak performance, regular care is essential.

Filter Cleaning

Air filters should be inspected and cleaned regularly to avoid clogging.

Bearing Lubrication

Lubricating bearings extends their life and reduces friction during operation.

Motor Inspection

Periodic checks ensure motors run efficiently without overheating.

Belt and Drive Checks

For belt-driven blowers, alignment and tension should be regularly maintained.

Housing and Impeller Cleaning

Dust and debris should be removed to maintain smooth airflow and prevent energy loss.

Choosing the Right Centrifugal Blower Unit

Selecting the ideal blower depends on factors like air volume, pressure requirements, noise tolerance, and space availability. Consulting HVAC and industrial experts ensures that the chosen unit matches the exact operational need.

Key selection criteria include:

-

Airflow capacity (CFM)

-

Static pressure requirements

-

Energy efficiency ratings

-

Installation space

-

Noise levels

-

Maintenance demands

Future of Centrifugal Blower Units

The future of centrifugal blowers is geared toward sustainability and smart control. With industries focusing on energy conservation, manufacturers are innovating to produce units with lower power consumption and higher performance. Integration with building automation systems will make blowers more adaptive and intelligent, leading to enhanced air quality and reduced operational costs.

Conclusion

A Centrifugal Blower Unit is a powerful, reliable, and versatile machine designed to deliver controlled airflow in a wide variety of applications. From HVAC systems in modern buildings to heavy-duty industrial plants, centrifugal blowers play a crucial role in ensuring efficiency, safety, and comfort.

With ongoing innovations such as energy-efficient motors, smart controls, and eco-friendly materials, the centrifugal blower continues to evolve into a more intelligent and sustainable solution for the future. Investing in the right Centrifugal Blower Unit not only enhances operational performance but also ensures long-term reliability and cost savings.